Description

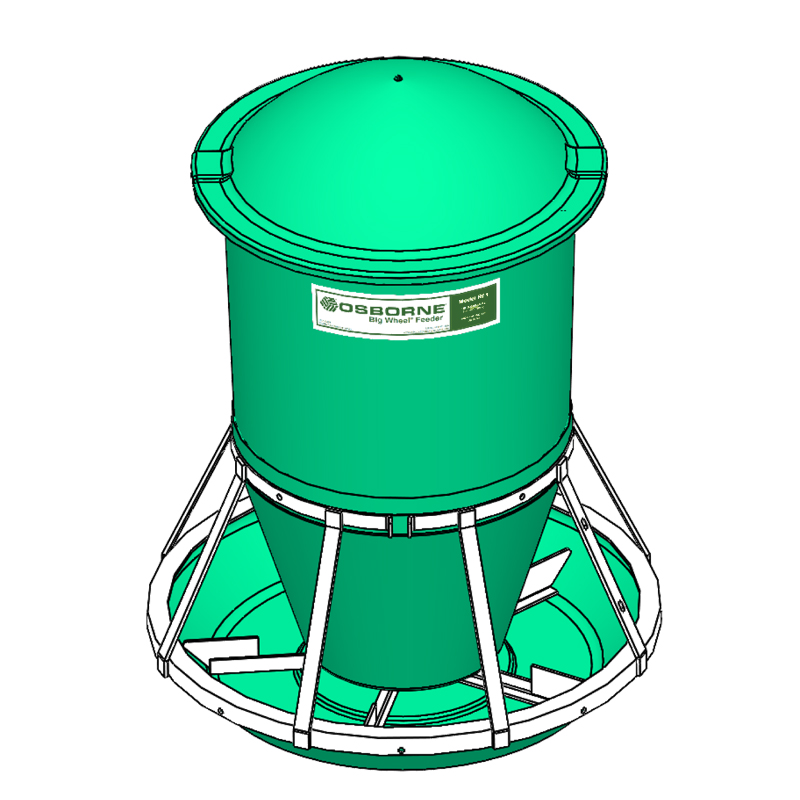

The Osborne RO45-Series Big Wheel Bulk Finishing Feeder provides fresh feed on demand for finishing pigs in outdoor lots, hoop-buildings, or pasture areas. Patented mechanical-flow feed delivery means pigs’ interaction with the feeder – not gravity – determines feed flow. This original Osborne-engineered design improves feed-to-gain ratios while almost completely eliminating waste. The round, self-cleaning trough provides pigs with a less stressful eating experience and 360-degree access to feed. Plugging is not a problem, even after heavy rains, because the self-cleaning action of the feeder always keeps feed flowing.

Big Wheel Feeders are manufactured with abrasion-resistant, reinforced fiberglass hoppers and troughs and hot-dipped galvanized steel metal parts. Shipped knocked-down on a pallet with complete assembly and operating instructions. Assembled feeders available by special order. Fiberglass-reinforced composite hopper lid with hatch door available by special order. A galvanized steel hopper lid is included with this model.

Features & Benefits

- Fresh feed always available

- Self-cleaning round trough with no corners for feed to accumulate

- Durable and rugged design for years of useful life

- Easy to clean

- Mechanical feed flow reduces feed waste more than gravity flow feeders

- Increase feed conversion rate

Specs

| Catalog Number | FF-0R045K |

| Model Number | RO45 |

| Feed Capacity* | 45 bu. 1.2 T (1.1 tonnes) |

| Height | 62 in. (158 cm) |

| Trough Diameter | 55.5 in. (141 cm) |

| Hog Weight | 50 lbs. (22.7 kg) to market |

| Hog Capacity | Up to 90 head |

Approximate feed capacity based on feed density of 42 lbs. per cubic foot.

Parts

Downloads

Frequently Asked Questions

- What does mechanical feed flow mean and how does it reduce waste?

The signature feature of Osborne’s Big Wheel Feeder design is its mechanical-flow feed delivery system. This means animals – not gravity – dispense the feed they need, and no more, which drastically reduces waste. Traditional feeders typically rely on gravity for feed to transfer from the feed hopper to the trough area. This design requires lots of manual adjustments as pigs grow and lots of overfilled troughs and waste. Big Wheel Feeders eliminate gravity flow by design. A unique system of parts inside the feed hopper stop gravity flow and requires animals to dispense the feed they need ad libitum. Overloading waste is eliminated by preventing feed dispensing when the trough is full. - How do I teach pigs to use the “Big Wheel”?

Animals quickly learn through play that the feed wheel in the trough area has to be rotated or moved back and forth for feed to dispense from the hopper. Big Wheel Feeder users typically fill the trough manually when first introducing animals to the feeder. As the first trough full is eaten, the pigs naturally begin playing and interacting with the wheel and quickly discover it helps in directing the feed to the outer trough area where it can be more easily consumed. - Why are through lids or covers not used?

Big Wheel Bulk Finish Feeder models work well outside – even when exposed to the elements – and plugging is rarely a problem. When the feeder is stocked with an adequate number of animals, water from rain or snow rarely overcomes the self-cleaning action of the feed wheel. Additionally, the position of the feed hopper in relation to the trough, accompanied by the Big Wheel’s mechanical-flow design, prevents moisture from “wicking up” and causing plugging issues. For feeders stocked with only a few animals, drilling a few weeping holes in the trough aides in moisture reduction before it can cause plugging problems. - Can I feed sows with a Big Wheel Bulk Finish Feeders?

Unlike finishing hogs, sows are not typically fed ad-libitum at all times. Big Wheel Feeders are all ad-libitum feeders, meaning animals can eat as much as they want at all times. Feeding sows in this manner for extended periods of time often leads to overweight animals which can affect breeding performance. While the large trough openings will accommodate most sows, feeding sows with an ad-lib feeder except during lactation is not recommended. - Can I stock a Big Wheel Bulk Feeder with less than 90 head?

While all Big Wheel Bulk Finish Feeders accept up to 90 head without feed restriction, a reduced number of animals may be stocked on the feeder. The only potential issue with under-stocking animals may be during extreme weather. See “Why are trough lids or covers not used?” for additional information.