Feeding Equipment

Feed is often the highest input cost in raising pigs. Eliminate waste and ensure pigs — not the pit or ground — are being fed with Osborne’s full line of automatic feeders, including Big Wheel Feeders and Electronic Sow Feeders (ESF) for group housing. Ranging from a one-bushel nursery feeder to a 2-plus ton-capacity bulk finishing feeder and a feature-loaded electronic sow feeding system, there’s an Osborne feeder for every pig farm.

About

Osborne pioneered a new concept for feeding pigs back when farmers had only traditional gravity-flow feeders to rely on. This concept, known as mechanical-flow feeding, boosted profit on livestock farms from both feed and labor savings.

The mechanical-flow feed delivery system in the Big Wheel Feeder works differently than traditional gravity-flow feeders. Mechanical-flow feed delivery means pigs — not gravity — operate the feeder, dispensing only what they need and no more. This design offers incredible feed savings by ensuring feed goes directly to the pigs instead of going to waste on the ground or in the pit. Guaranteed to offer a full return on investment, there really is nothing that beats a Big Wheel.

In addition to the Big Wheel Feeder, Osborne offers ESF systems that allow for individual sow feeding and management without individual confinement.

Join Osborne's thousands of satisfied customers — and hundreds of thousands of animals all over the world — by choosing an Osborne feeding system to meets your needs.

Wean-to-Finish Feeders

Provide the maximum amount of feed for newly weaned pigs and finish them with zero waste with Osborne’s FAST Start Big Wheel Feeders. Harnessing only the benefits of gravity-flow feed delivery for weaned pigs, FAST Start automatically converts to Osborne’s signature no-waste, mechanical-flow feed delivery as pigs grow. Grow and finish pigs all on a single feeder with FAST Start.

Finish Feeders

Used inside or outside, nothing beats the feed and labor-saving performance of the Big Wheel Finish Feeders. Large trough openings and plenty of standing room means pigs never waste feed from competing for access or overcrowding. Improve feed conversion by ensuring feed is going into the pigs and not the pit with Big Wheel Finish Feeders.

Bulk Finish Feeders

Reduce the labor required for constantly refilling feeders with Osborne’s automatic Big Wheel Bulk Finish Feeders. Hot-dipped galvanized metal parts and abrasion-resistant fiberglass-reinforced composite hoppers and troughs easily stand up to the abuse of Mother Nature and 300-lb. finish hogs. Perfect for growing pigs in hoop barns or on dirt lots.

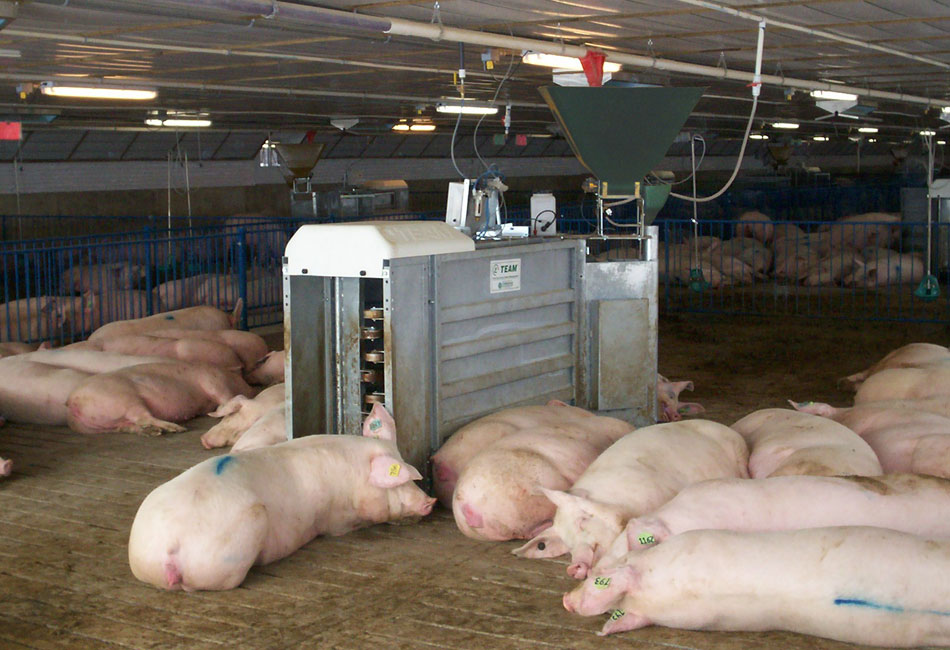

Pen Gestation Feeders (ESF)

Electronic Sow Feeding (ESF) allows for individual sow and gilt management without individual confinement. Harnessing radio frequency identification (RFID) technology, Osborne’s Total Electronic Animal Management (TEAM) systems provide animals with freedom to exercise, freedom to choose their eating schedule without feeding anxiety or aggression, and improves animal condition.

Literature

Big Wheel Feeder Catalog: English

FAST Start Big Wheel Wean-to-Finish Feeder Catalog: English

Big Wheel Feeder Frequently Asked Questions: English

Big Wheel Lactation Feeder Trial Facts: English

TEAM Electronic Sow Feeding (ESF) Catalog: English

TEAM ESF Frequently Asked Questions: English

Benefits of TEAM ESF: English

ACCU-TEAM ESF Catalog: English

News Articles

Genetic selection for docility is important in loose sow housing: English

Sows in Groups Preferred: English

Press Releases

SBIR Grant: English

USDA Grant: English

Osborne Introduces New Ad-Libitum Sow Feeder: English

Osborne Introduces New Wean-to-Finish Feeder: English

Pig Producer Presents Electronic Sow Feeding (ESF) System Experience: English | Chinese

NeX Eco Populates New Sow Farm With Animals: English | Chinese

Chinese Swine Integrator Purchases TEAM Electronic Sow Feeding (ESF) System: English | Chinese

Integrator Co-operative Installs First TEAM Group Sow Management System in Japan: English

New Alliance Will Improve Sow Herd Management: English

Past, Present and Future of Sow Housing at GDPIA Trade Show: English