Description

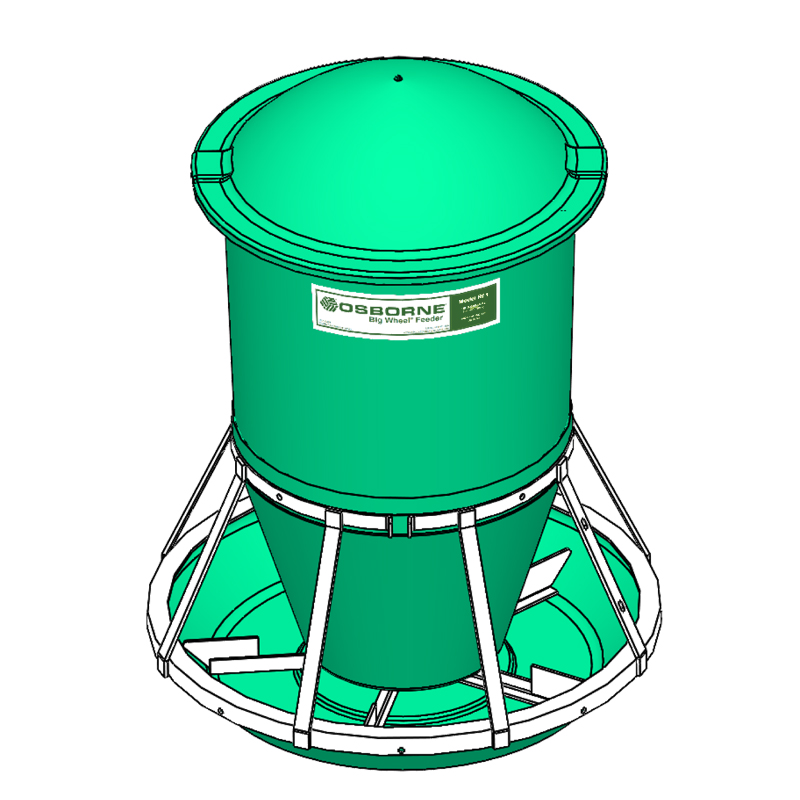

The Osborne RF2WFS-Series FAST Start Big Wheel Wet/Dry Wean-to-Finish Feeder provides fresh feed on demand for newly weaned pigs up to finishing weight. The unique design of the FAST Start feeding system allows it to operate in gravity-flow mode for the first 10-14 days before automatically converting to Osborne’s signature mechanical-flow design. Small slides in the feed hopper bottom remain open until pigs are strong enough to turn the feeder’s agitation wheel, allowing feed to free-flow into the trough. Once in mechanical mode, the feeder operates just as a standard Big Wheel Feeder. The wet/dry option for FAST Start improves feed palatability and feed consumption.

The FAST Start Big Wheel Wet/Dry Feeder is manufactured with abrasion-resistant, reinforced fiberglass hoppers and troughs and combination zinc plated/304 stainless steel metal parts. Shipped knocked-down on a pallet with complete assembly and operating instructions. Assembled feeders available by special order. Optional water pipe kit and vacuum water valve available, ordered separately.

IMPORTANT NOTE: While this feeder is rated for pigs from wean to market weight, some heritage breeds may have difficulty accessing feed as they approach market weight owing to their body type and trough divider opening size. Customers with heritage breeds should consider contacting Osborne Customer Service prior to making their purchase to discuss complete wean-to-finish feeding options.

Specs

| Catalog Number | FF-00RF2WFS (zinc plated/304 stainless steel) |

| Feed Capacity* | 235 lbs. (105 kg) |

| Height | 36 in. (91 cm) |

| Trough Diameter | 31 in. (79 cm) |

| Hog Weight | 10 lbs. (15.9 kg) to market |

| Hog Capacity | Up to 60 head |

Approximate feed capacity based on feed density of 42 lbs. per cubic foot.

Parts

Downloads

Frequently Asked Questions

- What does mechanical feed flow mean and how does it reduce waste?

The signature feature of Osborne’s Big Wheel Feeder design is its mechanical-flow feed delivery system. This means animals – not gravity – dispense the feed they need, and no more, which drastically reduces waste. Traditional feeders typically rely on gravity for feed to transfer from the feed hopper to the trough area. This design requires lots of manual adjustments as pigs grow and lots of overfilled troughs and waste. Big Wheel Feeders eliminate gravity flow by design. A unique system of parts inside the feed hopper stop gravity flow and requires animals to dispense the feed they need ad libitum. Overloading waste is eliminated by preventing feed dispensing when the trough is full. - How do I teach pigs to use the “Big Wheel”?

Animals quickly learn through play that the feed wheel in the trough area has to be rotated or moved back and forth for feed to dispense from the hopper. Big Wheel Feeder users typically fill the trough manually when first introducing animals to the feeder. As the first trough full is eaten, the pigs naturally begin playing and interacting with the wheel and quickly discover it helps in directing the feed to the outer trough area where it can be more easily consumed. - Can I use my Big Wheel Feeder outside?

Yes. Most Big Wheel Feeder models work well outside – even when exposed to the elements – and plugging is rarely a problem. When the feeder is stocked with an adequate number of animals, water from rain or snow rarely overcomes the self-cleaning action of the feed wheel. Additionally, the position of the feed hopper in relation to the trough, accompanied by the Big Wheel’s mechanical-flow design, prevents moisture from “wicking up” and causing plugging issues. For feeders stocked with only a few animals, drilling a few weeping holes in the trough aides in moisture reduction before it can cause plugging problems. - How does the round trough design of Big Wheel Feeders compare to rectangular feeders?

Rectangular feeders force pigs into close contact with one another. The round design of the Big Wheel Feeder spreads pigs radially around the trough, providing more standing-room space and less physical contact. Less physical contact means less wasteful competition. Linear trough space can never be fully used with rectangular feeders, and the Big Wheel’s round design occupies less space than comparable rectangular feeders. Big Wheel Feeders may also be installed in the center of a pen or in the fenceline to use one feeder to feed two separate groups.