This blog is Part One of our three-part series highlighting livestock ventilation system designs.

Livestock farmers understand how important maintaining their animals’ health and comfort is to their bottom line. Livestock ventilation systems contribute to profitability by helping to maintain good air quality not only for their animals but also for those who care for them. Whether animals are raised for their milk, eggs, or meat, properly ventilated livestock buildings help prevent disease while reducing animal stress and discomfort, which contributes to higher profitability.

That said, an improperly designed livestock ventilation system can reduce profits considerably if it affects animal performance or is not energy efficient. The type of livestock ventilation system that best suits a livestock farmer’s needs depends on a number of factors, including building type, flooring design, and waste-handling system, as well as the number, type, and age of livestock. All buildings in which animals are contained must have some form of ventilation. Below, we review important factors to keep in mind when considering livestock ventilation systems.

Factors to Consider with Livestock Ventilation Systems

First, let’s look at three basic features required to maintain an environment that keeps livestock healthy:

1. Sufficient air exchange

This helps to ensure fresh air continuously flows through structures.

Proper air exchange is often accomplished by a combination of exhaust fans and automatic fresh air inlets. A system control can automatically operate and adjust exhaust fans based on user inputs. Osborne ventilation experts offer free design services for all custom ventilation systems that maintain sufficient and efficient air exchange.

2. Ventilation rates that control and adjust the inside environment in relation to conditions outside

This can be done through the use of curtains, doors, or panels that can be opened and closed.

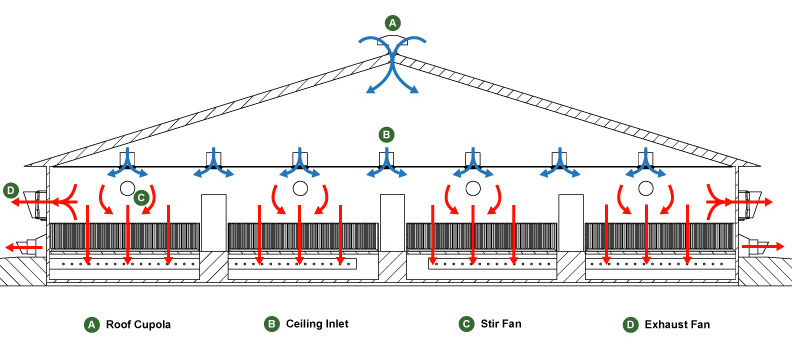

Western livestock barn designs accommodate several options for ventilation systems, but none are as effective as negative pressure systems that exhaust toxic indoor air and replace it with fresh air from outside. Specifically, in barns where pigs are raised, efficient negative-pressure systems bring fresh, outdoor air into attic or hallway spaces with roof cupolas or automatic wall inlets. Incoming air is tempered to better match indoor temperature conditions and then distributed inside the animal area with ceiling or hallway inlets. Fully-automatic air inlets, like the AUTO-Max series, eliminate the need for making manual adjustments to airflow based on outside climate or season.

Fresh air enters the barn attic through a roof cupola (A). The air is tempered in the attic and enters the building where animals are housed through ceiling inlets (B). Stir fans (C) mix the incoming fresh air, eliminating “dead air” spaces and keeping temperatures uniform. The air inside the barn is exhausted via exhaust fans (D) on the outside building walls and pulled through the slatted floors into the pit area. A system of air ducts in the pit pulls air down, reducing fumes from the pit from entering the animal area, and exhausting toxic gasses from the pit via the exhaust fans (D) attached to the air duct system.

3. The livestock ventilation system must be flexible

Depending on the season or climate, it’s important to have the ability to remove excess moisture produced by livestock and control temperatures to remove excess heat emanating from animals’ bodies.

The versatility and flexibility of stir fans, like the Super-Jet series, help to keep the fresh air brought in from the outside evenly distributed because they can be positioned anywhere inside the animal area.

As all the components of a properly designed ventilation system work together, livestock structures can offer increased oxygen supply while reducing the amount of dust, gas, odors, moisture and airborne organisms in the animals’ environment. Livestock ventilation systems help moderate the temperature and movement of air as well.

Importance of Efficient Livestock Ventilation Systems

All these factors directly affect livestock health. Managing livestock ventilation systems properly ensures animals are kept comfortable, which allows for optimal growth or production. Properly regulating indoor environments also helps keep animals from exhibiting behaviors related to stress, which can also negatively affect production.

Additionally, livestock ventilation systems help ensure the safety of those who work with animals in barns and other enclosed structures. Several types of toxic gases result from the accumulation of animal waste, especially in enclosed spaces. Though eventually moved to lagoons or containers outside the building, animal waste is first stored in liquid form under the facility or over slatted flooring.

The sudden release of a large amount of hydrogen sulfide gas has been implicated in the deaths of both farm workers and animals after agitating or emptying manure pits. Oftentimes the accumulation of animal waste can lead to a buildup of this gas, leading to serious illness or death, especially during winter when ventilation rates are at their lowest. Other fatal cases can occur when workers enter such pits to repair, inspect or retrieve an object dropped into it. Extra precaution must be taken and only experienced individuals should enter pits.

Part Two: Natural & Mechanical Ventilation

Follow along with our three-part series on livestock ventilation system designs. Our next blog will discuss the differences between natural ventilation and mechanical ventilation, as well as weigh the pros and cons of both.

To learn more about Osborne Livestock Equipment and our products, including the Agri-Aide Ventilation System, please contact us today.