Over the years, pig producers have often selected animals going to market by just visually inspecting them—a method that isn’t very accurate. Technology has transformed modern pig farming, bringing many advantages for both farmworkers and animals. Automation driven by pig management software makes farm operations much more efficient, allowing fewer workers to care for more animals. These same automated processes also lead to better care of animals, which improves a farm’s productivity, efficiency, and profitability.

Pig Management Software: Using Analytics Applications for Finishing

Very stringent standards exist for hog farmers when bringing their animals to market. When pigs do not fall within specified weight requirements, significant financial penalties are incurred on the farmers. Though perhaps the most important, weight is only one factor among many. Other issues, like overall health and injury, affect prices as well. For these and other reasons, an increasing number of farmers have turned to pig management software applications to give them an advantage over competitors.

Automated pig management software offers the following advantages:

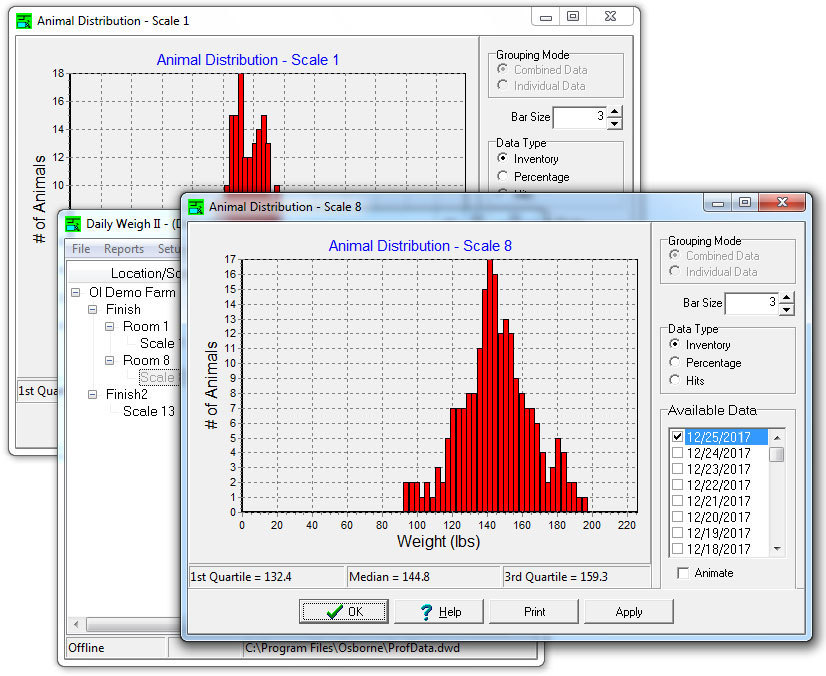

- Accurate predictions can be made using collected data. Modern pig management software, such as Osborne’s Weight Watcher Growth Management System, offers a means to visualize data through the use of charts and reports, allowing easy analysis and enabling accurate calculations about time frames for delivering hogs to market.

- Automated sorting of populations by weight, dietary requirements or other relevant information allows for earlier removal of hogs once they reach certain weights. This then allows smaller pigs to feed further in order to reach their target weight without being bullied by larger, more dominant hogs.

- Automatic feeding based on weight leads to fewer variations in weight among pigs. When in traditional pens, larger and heavier hogs dominate feeding troughs, becoming even larger, while smaller ones have less opportunity to feed and often never reach an ideal target weight.

- Automatic weighing uses automated scales that are supported by pig management software. These applications help reduce “pig sort loss,” a term used to describe and quantify the value lost due to wide variations in weights among hogs going to market. Such applications help separate pigs of different sizes, which involves scales being placed strategically between water and feeding pens in order to collect data on weight in real-time.

- Biometric sensor technology enabled by pig management software offers a way in which to monitor more animals with fewer employees, while still providing reliable and objective data on animal health and welfare. The relevant data collected includes weight gain, allowing more accurate forecasts on when to send hogs to market.

- Controlling disease becomes easier with automated systems, as it makes identifying and separating pigs that are sick or injured easier.

- Fewer deaths to pigs in pens and in transit result from automatically sorting pigs. University of Pennsylvania researchers conducted a study that found fewer pigs were found dead on arrival. The researchers attributed this to the pigs’ acclimation to bigger groups and pre-conditioning for walking in lines, both of which are features in most automated pig farming systems.

- Greater employee satisfaction results when staff recognizes the safer environment automation brings. This includes reducing the chance of illness from crossover diseases, largely due to a reduced need for direct contact between hogs and humans.

- Identifying problematic behaviors, such as altered eating habits, changes in water consumption, aggression, or other abnormal reactions, helps farmers evaluate trends among the animals. Often readily observable behaviors offer clues about potential disease outbreaks or stress-related aggression.

- Lower labor costs result from automation, including such labor-intensive tasks as sorting pigs for market.

- Safety during transfers to market or between pens improves when done automatically. Manual herding causes stress for both pigs and caretakers and can pose a danger of injury to both. When pig management software is combined with sorting systems, it significantly reduces the chance of injuries because the pigs are acclimated to moving between several pens and gates.

- Structuring diets for pigs with differing levels of weight gain or health conditions that require specific feed allows farmers to more easily separate animals into areas where they can reach target weights more quickly. Pig management software allows tracking between feeding cycles, allowing more precise nutrition suitable to individuals or groups of hogs.

- Withdrawing feed in a timely manner is made much easier through automation, as programs can automatically separate pigs into allocated pens once they’re ready to go to market. It makes adjusting feeding rations much easier as well, as it reduces feed costs by allowing targeted phase feeding.

- Worker productivity improves as each person is able to focus on an increased number of pigs due to time- and labor-saving aspects of automated systems.

Osborne Weight Watcher Pig Management Software

Osborne developed the original automated growth management system that utilizes both hardware and software to manage fattening pigs going to market, with systems able to accommodate 500-600 animals. Designed to work in harsh environments typical to livestock farming, Osborne’s Weight Watcher System maximizes animal comfort, monitors growth, accurately predicts time to market and gives farmers the ability to sort animals by any weight criteria.

Automated pig management software, like Osborne’s DailyWeigh application for large pen finishing, allows producers to monitor and review group growth trends, weight distributions, and more information collected by an automated sorting scale to assist in projecting time to market.

Osborne’s automated Weight Watcher system includes:

- Survey Scale that sorts by weight and auto-sorts hogs going to market.

- By-pass and one-way gates that allow easy access to pens with feed and water and ensure animals must cross the Survey Scale with each pass between the pens.

- Mechanical-flow feeders feed only when pigs interact with the feeding system, which minimizes waste.

- Sorting software that allows farmers to access, store and display data collected by the Survey Scale.

Osborne’s automated Weight Watcher System works by separating feed and water throughout the barn into individual zones, usually using the mechanical-flow Big Wheel Feeder for the feeding zones. It enables animals to move naturally between zones, with an automated sorting scale (Survey Scale) positioned to automatically weigh pigs and sort them as they pass through. This allows lighter-weight pigs to receive high-performance feed that accelerates weight gain and cuts downtime to market. It also allows heavier hogs to receive feed that maximizes return on gain in separate feed zones, reducing waste and increasing a farm’s profitability.

To learn more about Osborne’s automatic pig management software and equipment, please contact us today.